Präzision in jedem Accessoire

Wir besitzen unsere eigene Produktionsstätte, sodass wir die gesamte Fertigung intern durchführen können. Vom Designprozess bis

hin zur Serienproduktion verlassen sich unsere Kunden sowohl bei unserem Service als auch bei den Endprodukten auf unser hohes Qualitätsniveau.

Unser kundenspezifischer Hardware‑Prozess

Hier ein Überblick über unseren Prozess für kundenspezifische Hardware und darüber, wie wir alle Entwicklungsstufen abwickeln.

S1: Project Kickoff

When we first engage with customers, we conduct an in-depth needs assessment to fully uncover your product’s real requirements at the hardware level; through this process, we work with you to refine concepts into actionable solutions.

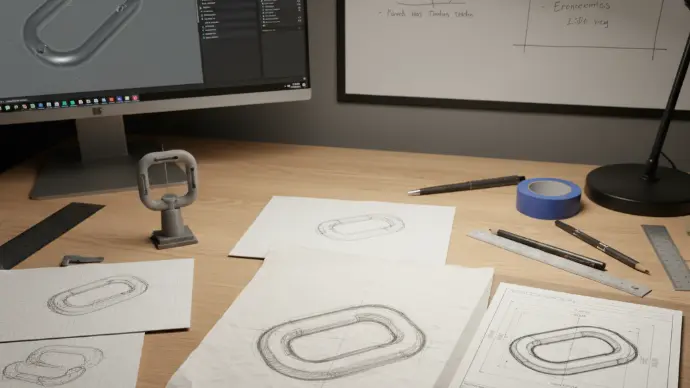

S2: Concept Creation

After reaching a consensus in the preliminary communication, we immediately start the prototype design of the hardware; whether the customer provides a sketch, a CAD model, or even a physical sample, we can quickly develop the initial structure and circuit plan based on it.

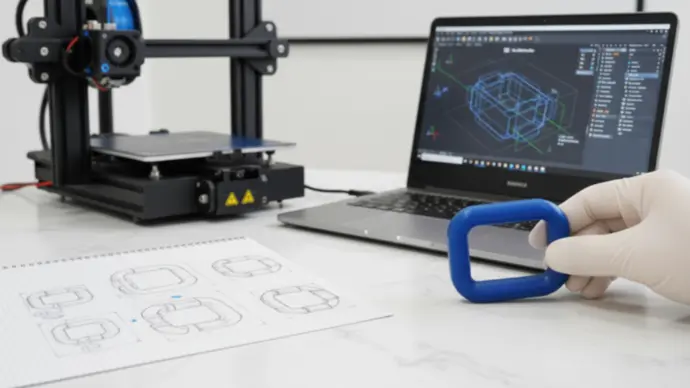

S3: 3D Visualization

After receiving your sketch or sample, we immediately convert it into a high-precision STL 3D model, which is then directly sent to our factory’s 3D printers to print a plastic prototype overnight—allowing you to see and touch a preliminary physical sample as soon as the next day.

S4: Sample Approval

Once the plastic prototype is approved, we will immediately begin final sampling—these samples will serve as the "master template," and will be directly used to replicate the mass production parent molds, ensuring that subsequent bulk goods are 100% consistent with the original design.

S5: Quality at Scale

nce the final sample is confirmed, we will seamlessly transition the project to the production line immediately. Whether you require a mass production of millions or a small trial order of a few hundred units, our factory can respond flexibly and deliver with precision.

S6: Final Delivery

After professional packaging of the finished hardware products, we can ship them directly worldwide; if you place an order from our Asian production line, we can also provide free full-container ocean shipping to your designated warehouse at any port of destination globally, with zero shipping cost and zero additional fees throughout the entire process.

Garantien und Schutzmaßnahmen

Wir überwachen die Servicequalität unserer Partner während des gesamten Prozesses, um sicherzustellen, dass Ihre Anforderungen nach höchsten Standards erfüllt werden. Sollten Probleme auftreten, werden wir ihre Lösung priorisieren und die geteilte Verantwortung übernehmen – Ihre Sorgenfreiheit hat für uns oberste Priorität.